Over Labor Day weekend, I spent an interesting week traveling for the first time to China! I set off with a colleague, our vice-president of business relations, Bob Burkhammer, and my buddy, Chris, who also works in the industry.

Our goal was to get ourselves to our glass manufacturing plant, a few hours outside of Beijing, to inspect the quality of several huge lites of glass, before they’re loaded onto a container and start to float their way to the US. We wanted to be sure that the quality was perfect before they hit the high seas for 6 weeks, to avoid any unnecessary delays, in case we spotted any issues.

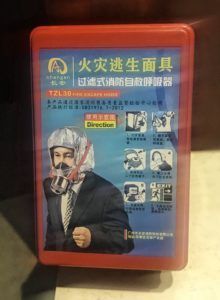

The getting there wasn’t so easy and took longer than our scheduled 24 hours. Our first flight was delayed and we missed our connection in Guangzhou, which meant an unplanned overnight stay. Luckily, the hotel was near the airport, and someone was there to guide us, but we all got a bit nervous when we saw that each room came supplied with these gas mask kits.

Our very patient liaison, Cherry Wang, of Shandong Paneu Glass Company, (who’d spent the night at the airport waiting for our delayed flight to land), arranged for our transportation needs and translated for us. She got us to the Luoyang NorthGlass plant, a partner plant of Paneu Glass, and where our glass was manufactured. This plant is renowned for having the capability of making huge pieces of glass, and we were blown away once we got inside.

The 1,100,000 square foot plant was both immense and immaculate. Not an extra scrap of anything was visible anywhere! To say you could eat off the floor would be an understatement. And everywhere we looked, we were so impressed by the surrounding technology, which included a suspended oversized glass transporting system, installed throughout the plant’s ceiling, from which were hung suction cups attached to pulleys. These cups attached onto the glass lites, the suction was adjusted to optimal grip levels, and the glass was then lifted by the pulleys. Glass would then start a journey through the plant, accompanied by just a few workers who strolled next to it, guiding it via intersecting ceiling tracks, all by remote control. Pretty amazing.

The glass we ordered is huge, and this is one of the few plants in the world which could make it. Ultimately, it will end up here in Southern California in what will be the largest collection of oversized glass in the US – or so we’re told. It’s for a confidential entertainment company managed by PCL Construction, and is due for completion in summer 2019.

The single largest piece measures 12’ high and 38’ wide, weighing in at almost 9,000 lbs. That’s just one of them, and there are a total of eight! The others are about the same height and range in width from 13’ to 36’ wide, and all are triple laminated plates of glass, 3 plys of ½” plates of low-iron glass. We inspected the glass for the usual suspects: wobbling, distortion, seeds, and checked the edges and the measurements, and all of it was perfect.

The craziest thing to consider is that this is NOT the biggest size glass this company can currently make. You can see that one – it’s this photo, and that (10.9 x 59 feet!) piece is on display at the plant, its metric measurements are written on the glass in red. They’re working on making even bigger pieces, as we speak.

Think of what it’s going to take to transport these! Over six weeks, they will travel across the ocean in a “convertible” (i.e. open top) container, inside custom wood crates built to hold each piece safely. The crate easily doubles the weight of the glass, and it’s going to take some massive cranes – and an additional set of power cups we just bought for the project to add to our collection, valued at over $20,000 – to get these positioned on the project site once they’re out of the container.

Our sincere thanks to a few folks. Garth Anderson, of Lucent Glass, our representative from British Columbia, Canada, responsible for getting our letter of invitation to China, arranging our hotel stays and handling the communications and logistics that made the meetings happen. Tim McNamara of Sino Source Enterprises, for getting us in touch with all the right folks and helping to make this production happen. He will also arrange for the transport of the final product all the way through to the job site, and that will be the subject of my next blog post on this project. We should start installing in mid-November, so please stay tuned!

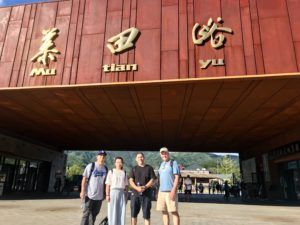

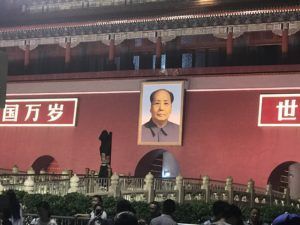

We managed to squeeze in little sightseeing, since we were so far from home. Here are a few of those shots: