As a great way to connect with Giroux Glass’ Western Region sales team and discuss all of the new product offerings, as well as learn even more about Viracon’s insulating, laminated and monolithic architectural glass products, we arranged a tour of their facility. Make no mistake, our main goal of this visit was to be educated on Viracon’s production and sales model, and to be offered feedback regarding strengths and opportunities.

An open invitation was sent to view the facility of one of the largest and certainly the best glass fabricator in North America, and among the best in the world. I reacted quickly understanding the rarity of such a trip. My fellow Giroux attendees were John Cox and Jessica Castillo. And myself, Duane Stanley (I’m based out of Arizona and represent most of Giroux’s Az projects from here). We want to give a huge shout out and thank Jack Paal of BPA Products our southern California Viracon rep for arranging everything and being a great host.

Although the visit required a sacrifice of personal/family weekend time, that time was rewarded with a nice dinner and a Vikings game on Sunday.

Here’s a quick recap of this epic tour: Viracon facility tour, located in Owatonna, Minnesota, from November 16th to the 18th, 2019.

Viracon strategically selects top customers from non-competing markets to create an environment of unity and camaraderie for mutual connections of best practices across common challenges in our industry. On Monday morning we made the 1 hour trip north to the Owatonna campus and were greeted with a presentation of product offerings, best practices, and propriety processes that define Viracon as an industry leader. The presentation was followed by a two-hour facility tour. Finally, we had a group discussion in review and round table open conversation regarding Viracon’s strengths and weaknesses.

Viracon strategically selects top customers from non-competing markets to create an environment of unity and camaraderie for mutual connections of best practices across common challenges in our industry. On Monday morning we made the 1 hour trip north to the Owatonna campus and were greeted with a presentation of product offerings, best practices, and propriety processes that define Viracon as an industry leader. The presentation was followed by a two-hour facility tour. Finally, we had a group discussion in review and round table open conversation regarding Viracon’s strengths and weaknesses.

The following were the main points of discussion:

The following were the main points of discussion:

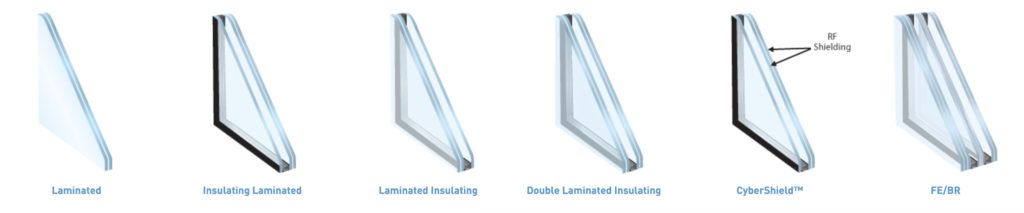

All of the variable configurations of Viracon Laminated Glass. The glass plies including high-performance glazing products available.

Legacy Lines – For typical sizing, typical make up, typical coatings, and units with banded spacer. These offer a slightly quicker lead time.

17/18 lines – For oversized glass, special coatings and make ups, and units with VTC spacer. These offer a slightly longer lead time.

Viracon’s strength in the post coating process of heat treated glass lites.

Heat Soak Testing – where and when it makes sense. The process and cost versus the consequential cost if not introduced to a project.

Glass flatness in terms of bend/warp , roller wave and lack of ASTM guidelines.

Anisotropy – European standards to measure visual distortion i.e. bend/warp and roller wave. This standard is slowly being introduced to the US market.

Oversized Glass: 130” x 236” max size capability.

Production Quality Assurance and Quality Control (QA/QC) processes throughout.

Mid Iron Glass – a more cost effective alternate to low-iron, which offers a very similar clarity.

Viracon coatings that are never discontinued.

Crating Logistics Program – Viracon is diligently working to create and utilize better crating, shipping, labeling, and tracking processes.

Brazil and Georgia locations.

Velocity Glass – Viracon subsidiary in TX. 100% automated and producing units with Vitro and Guardian coatings within a 500 mile radius of Dallas, TX.

Fun Fact: Viracon produces One Million square feet of glass every week; 52,000,000 SqFt of glass each year.