[one_second] [/one_second][one_second]

[/one_second][one_second] [/one_second]

[/one_second]

Press check: an event where sheets from a printing press are examined before authorizing full production to begin.

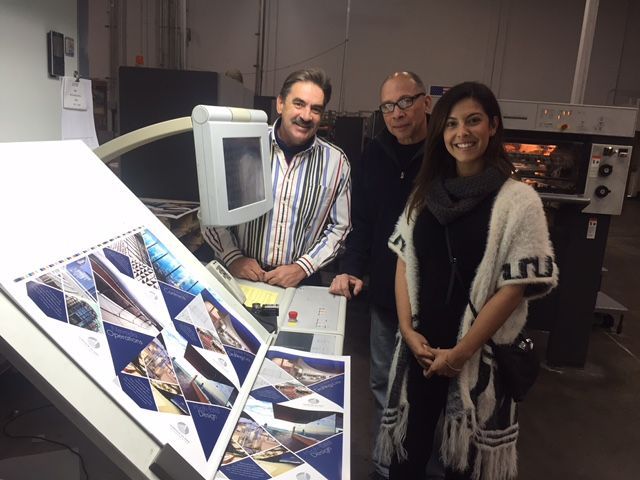

Just a few weeks ago, I experienced my very first on-site “press check” at James Litho, a printing company in Ontario, CA, when Barbara Kotsos (Giroux Glass’ Director of Marketing and PR) and I visited to approve prints of our beautiful, new company brochures, designed by JBrenlin Design.

It really was an incredible process to behold, and one loaded with history; first evidence of printing dates back to early Mesopotamian civilization before 3000 BCE, with lithography, the process that James Litho used for our brochures, discovered thousands of year later in 1796 Germany. But I digress a little….

Back at the James Litho facility, Bryan James was kind enough to give Barbara and I a complete tour of their machines and processes as we were waiting for proof sheets to print.

Back at the James Litho facility, Bryan James was kind enough to give Barbara and I a complete tour of their machines and processes as we were waiting for proof sheets to print.

We began at the “front end” of their business with their Heidelberg Speedmaster printer, a rather expensive, multi-million dollar piece of German equipment. Then, Bryan took us to their pre-press department, where basically all of the magic happens—“It all starts in the pre-press department. If your product isn’t right here, it will never get right out there,” Bryan said.

Barbara and I met their layout and production team: Peter, who does primarily large format and digital work, and Rick, the head of all pre-press processes. These guys spent a lot of time proofing our work to make sure the images were perfect before plates were made, and before anything hit the press—that’s where dollars start adding up, especially if the presses must be stopped for last minute changes to be made.

Proofing also included laying up documents on their “blue line” before plating, to minimize human error. Our images were laid out on a light table, and lines were drawn to ensure our documents were aligned and prepared for a metal plate to be printed. Once Barbara and I signed-off on the digital proofs, Rick made sure the margins, bleeds, and trim marks were exact. Then a machine processed the images to create ready-made plates, which would later be bent to the press and automatically set in the machine.

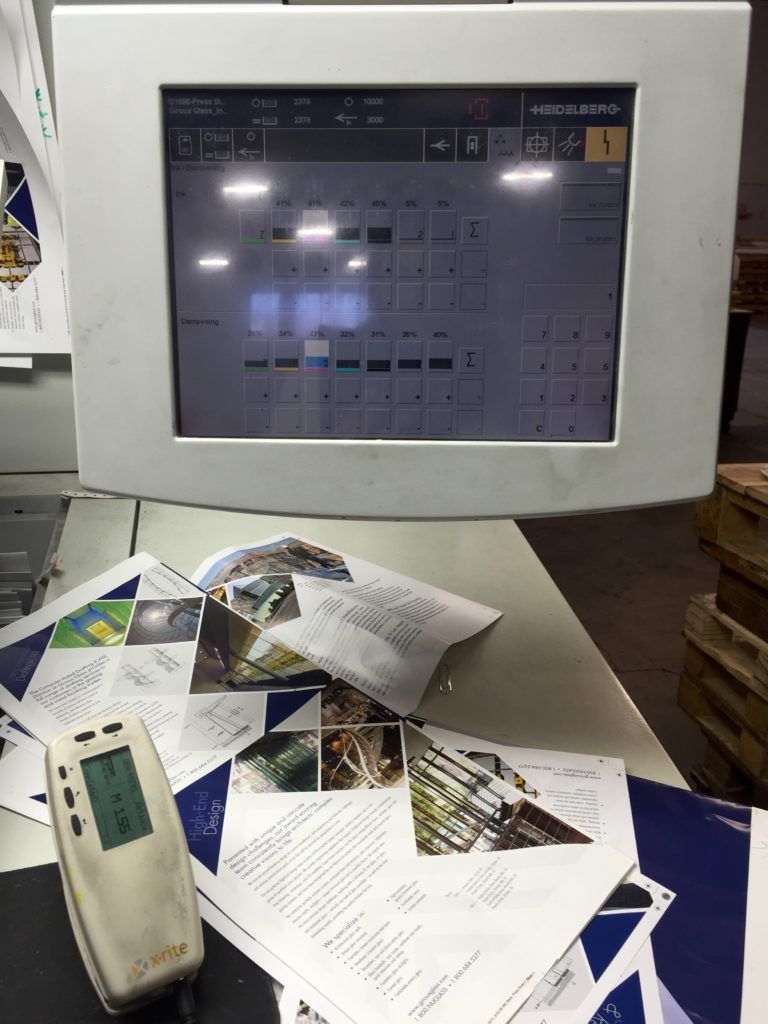

Another special Heidelberg device (shown right), operated by Trevor Wright, determined the coloring of each sheet, with each column of color specially determined by Trevor’s trained eye. The machine was reminiscent of a sound board or an equalizer, except for color. Once the machine was set and the sheets were printed, Barbara and I inspected each one for consistency and the right saturation of color. With that step complete, the production run began full-force!

Bryan explained just some of the processes of the Heidelberg Speedmaster machine that would produce our final product. And in case you’re curious about how the printer can work at a rate of 15,000 impressions/pages per hour (that’s roughly 4 pages per second)… the ink was loaded into the printer before it traveled from the fountain, to the plate (created earlier), to a blanket, and onto the final piece of paper. Everything was in reverse image when it hit the blanket. A cylinder in the printer came together, the blanket hit it, and what transferred the ink to the paper was the blanket, not the plate. Then, in order to stack the wet paper at such a fast rate, a heater was used and powder was distributed between each sheet—this is called offset printing.

Bryan explained just some of the processes of the Heidelberg Speedmaster machine that would produce our final product. And in case you’re curious about how the printer can work at a rate of 15,000 impressions/pages per hour (that’s roughly 4 pages per second)… the ink was loaded into the printer before it traveled from the fountain, to the plate (created earlier), to a blanket, and onto the final piece of paper. Everything was in reverse image when it hit the blanket. A cylinder in the printer came together, the blanket hit it, and what transferred the ink to the paper was the blanket, not the plate. Then, in order to stack the wet paper at such a fast rate, a heater was used and powder was distributed between each sheet—this is called offset printing.

This process led to cutting, scoring, and folding our sheets into the striking packets that are now our new Giroux Glass marketing brochures. The finished product of our department sheets and embossed, metallic folders can be seen here (right), where Barbara’s collating them, getting them ready for you, our customers and friends!

This was such a fun and challenging project for our Marketing team, and we thought it would be special to share it with you. Seeing this work come to life this past year, from graphic design, to the digital proofing and pre-press work, plating, printing, and so on, was a wonderful experience. It gave light to the art, science, and expertise required to create something that represents our company and reflects our Giroux Glass brand of quality, design, and customer service.

Thanks for reading!

by Monica Molinaro, Marketing and PR Assistant

Please share any questions or comments you may have with the author at [email protected].