A couple of weeks ago, coincidentally close to Labor Day, our Service Department did a pretty cool thing. They held a “Glass and Glazing Basics 101” course for those of us at Giroux Glass who are marketers, accountants, or clerks, and not trained PMs, Estimators, or Union glaziers.

We have a fairly diverse workforce at Giroux Glass. Many of our partners who work in our offices were, at one time, journeymen glaziers with years of field experience. Some underwent different training and experiences, while yet others are apprentices and skilled journeymen glaziers in our Local Unions 636 (Southern CA), LU 294 (Northern CA), and LU 2001 (Southern NV).

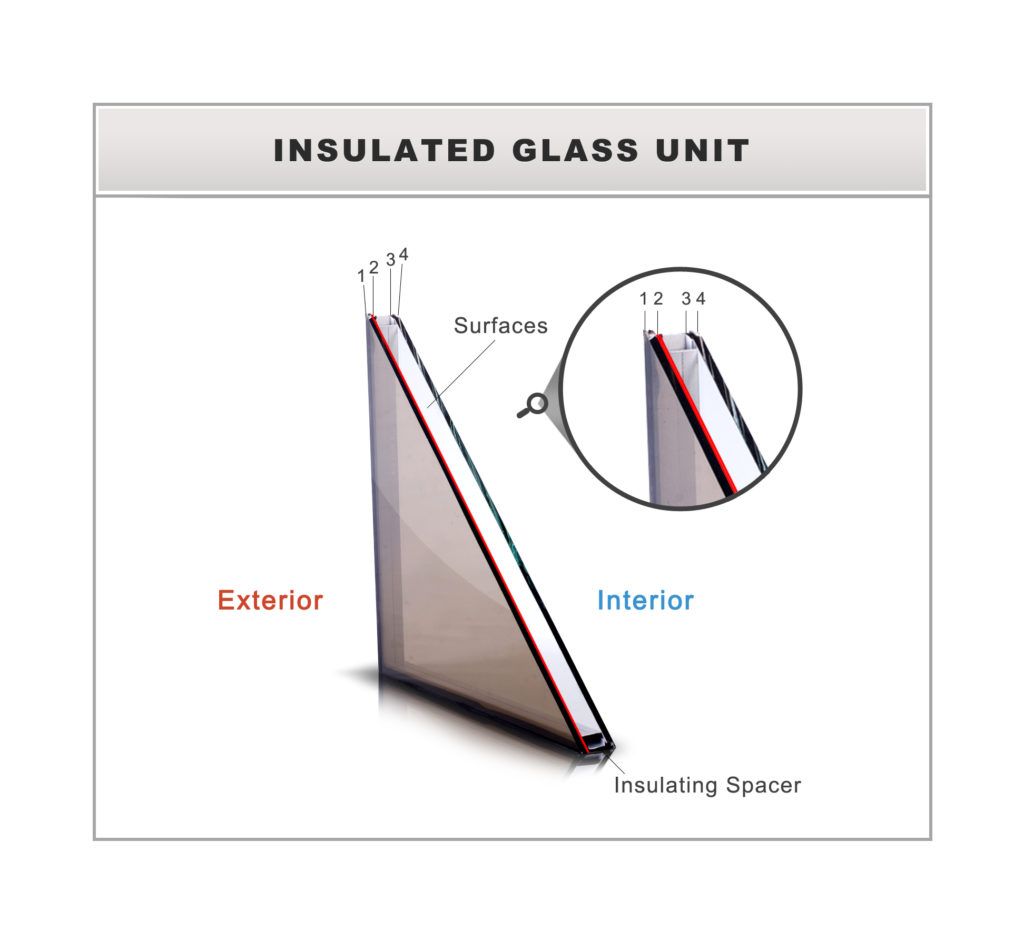

I’ve been in this industry for over 8 years now, but there is still much to learn about this niche within the AEC sector. In the GGB101 course, I’ll call it, there were some concepts that were new to me, such as which glass surface gets a tint or Low-E coating in an IGU (insulated glass unit), and how specific types of glass can account for sound transmission gains and losses, among other interesting topics.

I say it’s coincidental to be learning this around Labor Day because the subjects discussed in GGB101 represented just the tip of the iceberg of information which Union glaziers are trained to know. It’s quite amazing really–an art and a science.

I hope this post is helpful to those of you who are curious about glass and glazing, and also that it gives us all a greater appreciation for our labor forces and their incredible contributions and their socioeconomic achievements. The dedication of our glaziers and partners to their trade affects the strength, prosperity, and well-being of our company, our communities, and our country.

So, if you’ve made it this far into this blog post and would like to learn/refresh some of your basic glass and glazing knowledge, I’d love to begin sharing some concepts with you, straight from our Service Department (which has been around since 1946!).

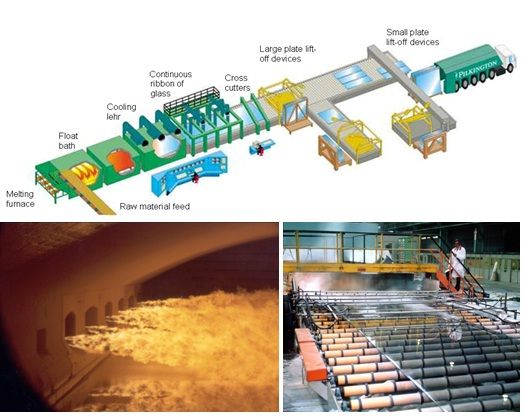

How glass is created: Glass (very much like ceramic glazes), is made by melting together silica and other minerals, such as soda ash and limestone, at extremely high temperatures–3092 degrees Farenheit. Other materials can be added to produce different colors or properties.

How glass is created: Glass (very much like ceramic glazes), is made by melting together silica and other minerals, such as soda ash and limestone, at extremely high temperatures–3092 degrees Farenheit. Other materials can be added to produce different colors or properties.

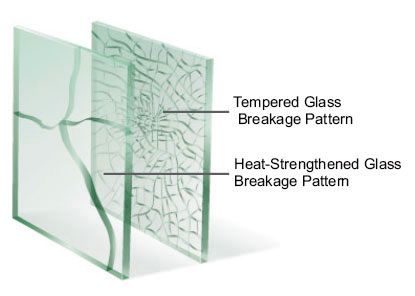

Glass statuses: Depending on fabrication, glass typically comes in raw (soft), heat strengthened, or tempered form.

Glass makeup: Glass is also frequently referred to as monolithic (one single lite), laminated, wire, spandrel (opaque), insulated (2 units with an airspace inbetween), insulated/laminated, tempered/laminated, and so on. Iron affects the color and clarity of glass; for example, low-iron starphire glass is clearer than typical “clear” glass which has more iron and thus more impurities.

Lamination: This is the process of “sandwiching” a PVB inner layer with lites of annealed, heat strengthened or tempered glass on either side. PVB (polyvinyl butyral) comes in various colors and thicknesses. XIR is a Low-E inner layer for laminated glass which deflects heat and prevents fading.

Low-E glass: Low emissivity glass reduces heat which travels through glass. The pyrolytic (hard coat) is molecularly bonded in the glass (as opposed to a coating) and cannot be removed or damaged. The color of Low-E glass changes depending on the manufacturer producing the glass.

Glass surfaces: First, always read from the outside of a building. The outside surface is referred to as the #1 surface, the inside surface is #2. Depending on the glass unit, you could have 6 or more surfaces altogether in one unit.

Measuring: There are 144 inches in one square foot of glass (12″ x 12″). Union glaziers knows to measure the width/horizontal dimension of an opening or glass first. The height/vertical dimension is always second. Ex: 100″ x 100″ = 10,000 sq.inches / 144 = 69.44 sq.ft.

Measuring: There are 144 inches in one square foot of glass (12″ x 12″). Union glaziers knows to measure the width/horizontal dimension of an opening or glass first. The height/vertical dimension is always second. Ex: 100″ x 100″ = 10,000 sq.inches / 144 = 69.44 sq.ft.

Glass weights per square foot: 1/8″ thick glass is 1.64 lbs. per sq.ft., 1/4″ thick glass is 3.27 lbs. per sq.ft., 1/2″ is 6.54 lbs. per sq.ft., and 1″ is 13.11 lbs. per sq.ft.

Glass height restrictions: Union glaziers are also trained to be aware of meeting height restrictions in partition wall glass panels. For example, 3/8″ tempered glass should be at most, 96″ at its longest dimension.

Cause of glass breakage: Heat stress, impact breaks, flaws, cat eyes, inclusions, shifting, spontaneous breaks, and heat retention from the surface film on raw glass are all possible causes. They tend to occur less frequently with tempered glass.

Types of glass breaks: Glass breaks differently depending on its make-up and fabrication. Raw-anneal (or float) glass breaks in large, sharp pieces; heat strengthened glass breaks in large pieces but keeps in place better; and tempered glass shatters throughout the unit and is the safest kind of break.

Types of glass breaks: Glass breaks differently depending on its make-up and fabrication. Raw-anneal (or float) glass breaks in large, sharp pieces; heat strengthened glass breaks in large pieces but keeps in place better; and tempered glass shatters throughout the unit and is the safest kind of break.

Glass cleaning tips: Use vinegar and water, de-natured alcohol, or an orange/citrus-based solvent (it contains no harmful abrasives and also removes film adhesives).

For even more learning, visit sites such as the NGA‘s or GANA’s, or give us a call at 213-747-7406.