From an architectural perspective, bent glass applications have a stunning visual impact, adding dynamism, flow, and captivating lines to the constructions in which they appear. From a glazing standpoint, bent glass requires special considerations in manufacturing and installation to ensure the design is executed as planned.

Material Considerations

Bent glass is more expensive to produce than standardized glass units due to the amount of labor required. Prior to production, the radius and other dimensions of the curved installation must be laid out to correspond with on-site references or control points. All parties involved in this stage of preparation must communicate effectively to ensure that the proposed configuration is as accurate as possible, and to minimize any wasted time or material.

Fabrication involves its own set of detailed processes, and additional costs may be incurred at every stage. Due to its custom curvature, bent glass may require multiple rounds of fabrication to achieve the radial dimensions required for the project’s design. The bending process may also warp or damage the surface of the glass, causing optical distortions on the finished product that may require re-fabrication. Depending on the size or composition of the bent glass, the product may have to be sourced overseas. Foreign products require longer lead times overall, which may be further compounded if any of the glass arrives damaged, or in the incorrect configuration.

If the bent glass does not arrive in time, contract glaziers typically work with the general contractor and project owner to determine an effective substitute material. To prevent any potential schedule delays, we recommend the use of acrylic, epoxy, or polycarbonate as temporary substitutes. These can be manufactured to custom radii more efficiently than glass. These temporary substitutions can be manufactured to the exact dimensions and design of the bent glass components, and provide a suitable temporary stand-in, or in some instances, permanent alternative to the bent glass in the projects.

Installation

Installation of bent glass presents its own unique set of considerations. Transporting curved pieces to the worksite requires larger crating and hoisting equipment than standard flat glass. Coordination with other trades is also essential, especially if another subcontractor will be interacting with the bent glass in their work. Finally, we execute the installation with extreme caution, as there is less, and sometimes no room for error based on the glass radius, compound bend, or bite when matching a radius frame. The less we need to adjust the glass into position, the better, as bent glass frames contain fewer removable stops to guide the pieces into place.

Rewards

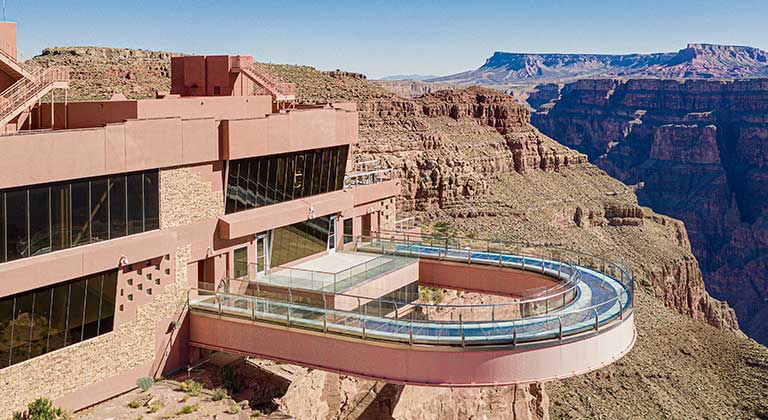

Bent glass applications can be used to expand the form and function of a space, provide wider and more scenic viewing experiences, and add visual interest to facades and interiors alike. When it comes down to it, bent glass expands the possibilities of design through glass, and makes the world— and our work—more interesting as a result.

This article originally appeared in USGlass magazine, volume 56, issue 2, February 2022