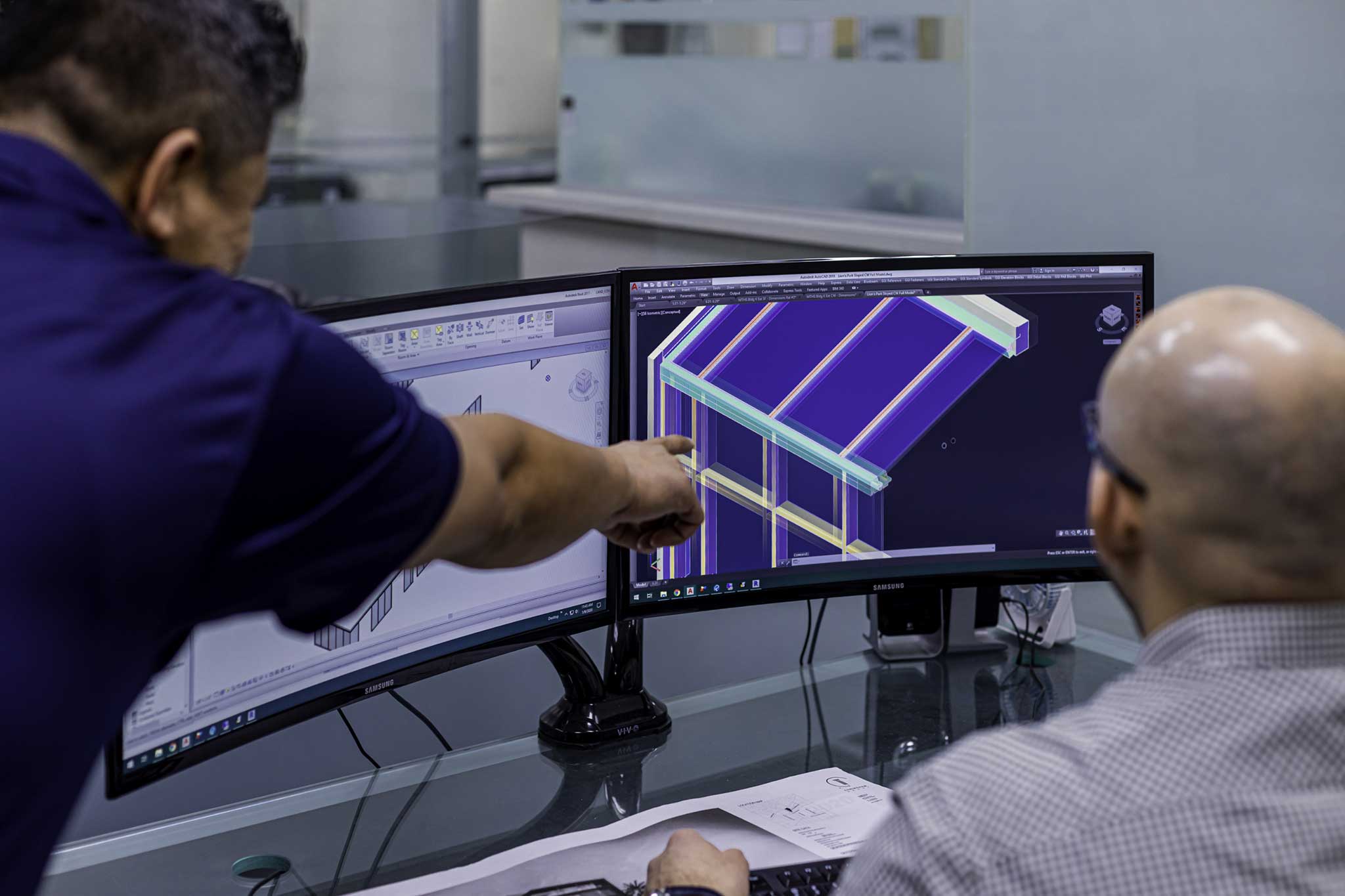

We’re the Experts Every Step of the Way

Giroux Glass has the tools and proficiency to create custom building exteriors from start to finish. From choosing the right design and materials for the job to custom panel fabrication, to installation, we can produce the ideal panel and/or glass system for your unique project.